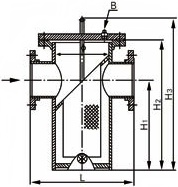

直通籃式過濾器是一(yi)種利用筒(tong)(tong)(tong)(tong)體(ti)(ti)(ti)內(nei)裝置(zhi)的濾(lv)籃,對(dui)液態及氣態介質(zhi)中的固體(ti)(ti)(ti)雜質(zhi)進行過濾(lv),從(cong)而使(shi)物料滿(man)足工藝(yi)設計要(yao)求,保證泵(beng)、壓縮機、儀表(biao)等正(zheng)常(chang)穩(wen)定運行的法(fa)蘭連接(jie)(jie)直通平(ping)底籃式過濾(lv)器。其(qi)筒(tong)(tong)(tong)(tong)體(ti)(ti)(ti)由(you)主管(guan)、接(jie)(jie)管(guan)、法(fa)蘭和底部平(ping)板(ban)(ban)組(zu)焊而成(cheng)(cheng),進出口在同一(yi)根軸(zhou)線(xian)上,上口成(cheng)(cheng)45°斜口的濾(lv)籃正(zheng)置(zhi)于筒(tong)(tong)(tong)(tong)內(nei)橢圓環形濾(lv)網(wang)支撐座上,并(bing)通過蓋板(ban)(ban)壓緊固定,當(dang)(dang)流體(ti)(ti)(ti)從(cong)入口流入筒(tong)(tong)(tong)(tong)體(ti)(ti)(ti)中后從(cong)上方(fang)進入濾(lv)籃內(nei)腔,經濾(lv)網(wang)過濾(lv)后從(cong)四周流入籃狀濾(lv)筒(tong)(tong)(tong)(tong)外(wai)壁與筒(tong)(tong)(tong)(tong)體(ti)(ti)(ti)內(nei)壁之間的空間內(nei),然后經出口流出,其(qi)中的固體(ti)(ti)(ti)顆粒則沉積在濾(lv)籃內(nei)。本產品的核心部件是由(you)濾(lv)筒(tong)(tong)(tong)(tong)和濾(lv)網(wang)組(zu)成(cheng)(cheng)的濾(lv)籃,其(qi)中濾(lv)筒(tong)(tong)(tong)(tong)通常(chang)采用不銹鋼材(cai)質(zhi)制作(zuo),當(dang)(dang)液體(ti)(ti)(ti)及氣體(ti)(ti)(ti)物料或工藝(yi)過程對(dui)濾(lv)筒(tong)(tong)(tong)(tong)材(cai)料有特殊要(yao)求時,可選用其(qi)他材(cai)料。

| 序號 | 部件名稱 | 材料名稱 | |||||

| 1 | 筒 體 | 20# | 15CrMo | 304 | 304L | 316 | 316L |

| 2 | 接 管 | 20# | 15CrMo | 304 | 304L | 316 | 316L |

| 3 | 支 撐 座 | Q235-B | 15CrMo | 304 | 304L | 316 | 316L |

| 4 | 法 蘭 | A105 | 15CrMo | 304 | 304L | 316 | 316L |

| 5 | 墊 片 | 聚四氟乙烯、金屬環形墊、金屬纏繞墊(帶內外環) | |||||

| 6 | 蓋 板 | Q235-B | 15CrMo | 304 | 304L | 316 | 316L |

| 7 | 平 底 | Q235-B | 15CrMo | 304 | 304L | 316 | 316L |

| 8 | 濾 籃 | 304 | 304 | 304 | 304L | 316 | 316L |

| 9 | 螺 塞 | 304 | 304 | 304 | 304L | 316 | 316L |

| 公稱壓力PN(MPa) | 1.0 | 1.6 | 2.5 | 4.0 | 2.0 | 5.0 |

| 殼體試驗壓力(MPa) | 1.5 | 2.4 | 3.75 | 6.0 | 3.0 | 7.5 |

| 氣密性試驗壓力(MPa) | 1.0 | 1.6 | 2.5 | 4.0 | 2.0 | 5.0 |

| 設計制造 | SH/T 3411-2017、HG/T 21637-2021、JB/T 7538-2016 | |||||

| 法蘭標準 | JB/T 81~82、GB/T 9115~9119、HG/T 20592~20615、SH/T 3406、ASME B16.5等 | |||||

| 檢驗驗收 | SH/T 3411-2017、HG/T 21637-2021、JB/T 7538-2016 | |||||

| 濾網規格 | 2目 ~ 600目 | |||||

| 公稱壓力 PN | 公稱通徑 DN | 結構尺寸/mm | 排放口 B | ||||

| D1 | L | H1 | H2 | H | |||

| 16 | 25 | 89 | 220 | 160 | 260 | 480 | R ? |

| 32 | 89 | 220 | 165 | 270 | 495 | R ? | |

| 40 | 114 | 280 | 180 | 300 | 550 | R ? | |

| 50 | 114 | 280 | 180 | 300 | 550 | R ? | |

| 65 | 140 | 330 | 220 | 350 | 650 | R ? | |

| 80 | 168 | 340 | 260 | 400 | 740 | R ? | |

| 100 | 219 | 420 | 310 | 470 | 880 | R ? | |

| 150 | 273 | 500 | 430 | 620 | 1175 | R ? | |

| 200 | 325 | 560 | 530 | 780 | 1495 | R ? | |

| 250 | 426 | 660 | 640 | 930 | 1810 | R ? | |

| 300 | 478 | 750 | 840 | 1200 | 2310 | R ? | |

| 表中未列出的其他規格參數,請咨詢汗越閥門技術部! | |||||||