<tr id='63hys'><strong id='63hys'></strong><small id='63hys'></small><button id='63hys'></button><li id='63hys'><noscript id='63hys'><big id='63hys'></big><dt id='63hys'></dt></noscript></li></tr><ol id='63hys'><option id='63hys'><table id='63hys'><blockquote id='63hys'><tbody id='63hys'></tbody></blockquote></table></option></ol><u id='63hys'></u><kbd id='63hys'><kbd id='63hys'></kbd></kbd>

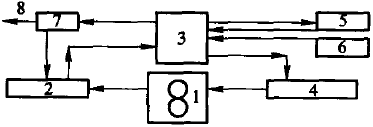

圖1示出油品過濾器過(guo)濾(lv)系(xi)統的(de)(de)(de)工(gong)作原理。從軋機出來的(de)(de)(de)臟油(you)(you)(you)流人到臟油(you)(you)(you)箱,泵(beng)將臟油(you)(you)(you)箱中的(de)(de)(de)油(you)(you)(you)送(song)(song)至(zhi)(zhi)主(zhu)過(guo)濾(lv)罐(guan),過(guo)濾(lv)后的(de)(de)(de)油(you)(you)(you)送(song)(song)至(zhi)(zhi)干凈(jing)油(you)(you)(you)箱。為(wei)了保證主(zhu)罐(guan)內濾(lv)芯工(gong)作正(zheng)常和延長(chang)濾(lv)芯壽命,系(xi)統每(mei)隔一定(ding)時間要進(jin)行一次反沖(chong)洗(xi),反沖(chong)洗(xi)前先停止過(guo)濾(lv),同(tong)時將主(zhu)罐(guan)內的(de)(de)(de)油(you)(you)(you)抽到中間箱,然后用壓(ya)縮(suo)空(kong)氣將濾(lv)芯上的(de)(de)(de)污(wu)(wu)物吹掉(diao)。反沖(chong)洗(xi)下來的(de)(de)(de)污(wu)(wu)物又由泵(beng)抽到污(wu)(wu)油(you)(you)(you)過(guo)濾(lv)系(xi)統中,經(jing)二次過(guo)濾(lv)的(de)(de)(de)油(you)(you)(you)送(song)(song)至(zhi)(zhi)臟油(you)(you)(you)箱,濾(lv)出的(de)(de)(de)污(wu)(wu)物經(jing)排(pai)污(wu)(wu)口排(pai)掉(diao)。

圖1 油品過濾系(xi)統工作(zuo)原(yuan)理

1-軋機(ji);2-臟油(you)(you)箱(xiang)(xiang);3-主過(guo)濾器;4-干凈油(you)(you)箱(xiang)(xiang);5-中(zhong)轉(zhuan)油(you)(you)箱(xiang)(xiang);6-壓縮空氣;7-污油(you)(you)過(guo)濾系(xi)統;8-排污口(kou)

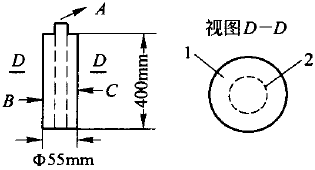

圖2示出了(le)目前按標準設計的濾(lv)(lv)(lv)(lv)(lv)芯外(wai)觀和尺寸。過(guo)(guo)濾(lv)(lv)(lv)(lv)(lv)系統工(gong)作時(shi)臟(zang)油從(cong)濾(lv)(lv)(lv)(lv)(lv)材外(wai)部(bu)(B、C方(fang)向(xiang))進入,經過(guo)(guo)濾(lv)(lv)(lv)(lv)(lv)材過(guo)(guo)濾(lv)(lv)(lv)(lv)(lv)后的凈油從(cong)A 管(guan)內(nei)被泵抽出。油中的金(jin)(jin)屬粉(fen)末(mo)被阻在過(guo)(guo)濾(lv)(lv)(lv)(lv)(lv)層外(wai)面,但(dan)有少量(liang)金(jin)(jin)屬粉(fen)末(mo)進入濾(lv)(lv)(lv)(lv)(lv)材內(nei)部(bu);反沖洗時(shi)濾(lv)(lv)(lv)(lv)(lv)芯內(nei)的大部(bu)分粉(fen)末(mo)被吹出,但(dan)工(gong)作時(shi)進入其內(nei)部(bu)的量(liang)大于反吹出的量(liang)。當金(jin)(jin)屬粉(fen)末(mo)全部(bu)進入濾(lv)(lv)(lv)(lv)(lv)芯內(nei)層(接近圖2中的出油管(guan))時(shi),濾(lv)(lv)(lv)(lv)(lv)芯的壓(ya)差很高(gao),流量(liang)下降,此時(shi)濾(lv)(lv)(lv)(lv)(lv)芯報(bao)廢(fei)。

圖2 濾芯結構

1-濾材(cai)(過濾層);2-Φ20mm 出油管