<dfn id='4oeOe'><optgroup id='A5hpx'></optgroup></dfn><tfoot id='o6PrR'><bdo id='EPgaw'><div id='5beBC'></div><i id='hvyoK'><dt id='9kKnR'></dt></i></bdo></tfoot>

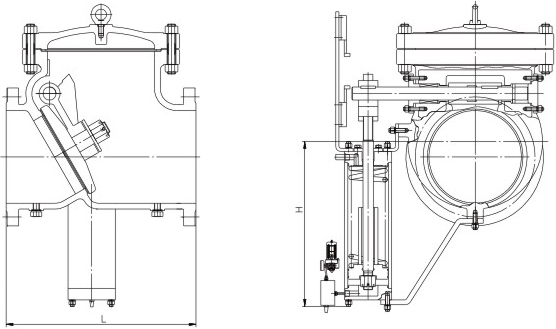

抽汽止回閥是(shi)一種適(shi)用(yong)(yong)(yong)于(yu)電站汽輪(lun)機(ji)(ji)(ji)系(xi)統(tong),能(neng)在(zai)(zai)機(ji)(ji)(ji)組發(fa)生故障時(shi)(shi),根據控制系(xi)統(tong)的指(zhi)令快速關(guan)(guan)(guan)閉(bi)(bi),并可在(zai)(zai)抽(chou)汽管道內介質反流(liu)時(shi)(shi)自動(dong)(dong)(dong)封(feng)(feng)(feng)閉(bi)(bi),從而保(bao)(bao)障汽輪(lun)機(ji)(ji)(ji)系(xi)統(tong)正常(chang)工(gong)作的側(ce)置氣(qi)動(dong)(dong)(dong)蓄(xu)能(neng)旋啟式抽(chou)汽止回閥(fa),其在(zai)(zai)接到關(guan)(guan)(guan)閉(bi)(bi)信(xin)號(hao)后(hou)具(ju)有快速關(guan)(guan)(guan)閉(bi)(bi)的性能(neng),關(guan)(guan)(guan)閉(bi)(bi)時(shi)(shi)間滿(man)足汽輪(lun)機(ji)(ji)(ji)系(xi)統(tong)保(bao)(bao)護的要(yao)求,從全(quan)開到全(quan)關(guan)(guan)(guan)用(yong)(yong)(yong)時(shi)(shi)不超(chao)過0.5s。該閥(fa)流(liu)道采(cai)用(yong)(yong)(yong)流(liu)線形設計,流(liu)體阻(zu)力(li)小,閥(fa)瓣(ban)經搖桿與閥(fa)軸活動(dong)(dong)(dong)連接,閥(fa)瓣(ban)繞(rao)閥(fa)軸旋轉,可以(yi)使(shi)閥(fa)瓣(ban)準確(que)的落在(zai)(zai)閥(fa)體密(mi)封(feng)(feng)(feng)面(mian)上,保(bao)(bao)證密(mi)封(feng)(feng)(feng)面(mian)的吻合,閥(fa)體密(mi)封(feng)(feng)(feng)面(mian)傾斜相(xiang)(xiang)應(ying)角度,以(yi)減少閥(fa)門關(guan)(guan)(guan)斷時(shi)(shi)間,減輕沖擊。本產品執(zhi)行機(ji)(ji)(ji)構與閥(fa)門啟閉(bi)(bi)件動(dong)(dong)(dong)作相(xiang)(xiang)互獨立,氣(qi)缸故障不影響閥(fa)瓣(ban)關(guan)(guan)(guan)閉(bi)(bi)動(dong)(dong)(dong)作,具(ju)備防止氣(qi)動(dong)(dong)(dong)裝置失效的功(gong)能(neng),能(neng)在(zai)(zai)氣(qi)缸出(chu)現卡阻(zu)情況下,仍(reng)能(neng)夠在(zai)(zai)介質力(li)作用(yong)(yong)(yong)下關(guan)(guan)(guan)閉(bi)(bi),以(yi)確(que)保(bao)(bao)汽輪(lun)機(ji)(ji)(ji)系(xi)統(tong)安然無恙。

| 序號 | 部件名稱 | 材料名稱 | |||||

| 1 | 閥 體 | WCB | WC1 | WC6 | WC9 | C12A | ZG20CrMoV |

| 2 | 閥 瓣 | WCB | WC1 | WC6 | WC9 | C12A | ZG20CrMoV |

| 3 | 搖 桿 | WCB | WC1 | WC6 | WC9 | C12A | ZG20CrMoV |

| 4 | 閥 軸 | 2Cr13 | 304 | 304 | 304 | 316 | 304 |

| 5 | 閥 蓋 | WCB | WC1 | WC6 | WC9 | C12A | ZG20CrMoV |

| 6 | 填料壓蓋 | WCB | WC1 | WC6 | WC9 | C12A | ZG20CrMoV |

| 7 | 填 料 | GRAPHITE | GRAPHITE | GRAPHITE | GRAPHITE | GRAPHITE | GRAPHITE |

| 8 | 氣 缸 | 20 | 20 | 20 | 20 | 20 | 20 |

| 9 | 彈 簧 | 60Si2Mn | 60Si2Mn | 60Si2Mn | 60Si2Mn | 60Si2Mn | 60Si2Mn |

| 公稱壓力PN(MPa) | 1.6 | 2.5 | 4.0 | 6.3 | 10.0 | 16.0 |

| 殼體強度試驗壓力(MPa) | 2.4 | 3.75 | 6.0 | 9.45 | 15.0 | 24.0 |

| 液體密封試驗壓力(MPa) | 1.76 | 2.75 | 4.4 | 6.93 | 11.0 | 17.6 |

| 氣體密封試驗壓力(MPa) | 0.5~0.7 | 0.5~0.7 | 0.5~0.7 | 0.5~0.7 | 0.5~0.7 | 0.5~0.7 |

| 設計制造 | JB/T 12002、DL/T 1822、NB/T 47044、ASME B16.34 | |||||

| 結構長度 | GB/T 12221、DL/T 1822、ASME B16.10 | |||||

| 法蘭標準 | JB/T 79、GB/T 9124.1、HG/T 20592、ASME B16.5等 | |||||

| 檢驗試驗 | GB/T 13927、NB/T 47044、API 598 | |||||

| 公稱壓力 PN | 公稱通徑 DN | 外形尺寸/mm | 公稱壓力 PN | 公稱通徑 DN | 外形尺寸/mm | ||

| L | H | L | H | ||||

| 16 | 80 | 356 | 375 | 25 | 80 | 356 | 375 |

| 100 | 457 | 445 | 100 | 457 | 445 | ||

| 125 | 508 | 485 | 125 | 508 | 485 | ||

| 150 | 559 | 525 | 150 | 559 | 535 | ||

| 200 | 660 | 715 | 200 | 660 | 745 | ||

| 250 | 787 | 975 | 250 | 787 | 1020 | ||

| 以上尺寸僅供參考,表中未列出的其他規格參數,請咨詢汗越閥門技術部! | |||||||

為了使本產品順利打開和穩定運行,并能夠快速關閉,大口徑的本閥配有重錘,位置可調整,出廠前位置基本調好(見刻線標志),運行前可根據情況稍做調整。如果你需訂購我廠電站閥系列產(chan)品,咨詢時煩請說明公(gong)稱通徑(jing)、公(gong)稱壓力、材(cai)質(zhi)、使(shi)用介質(zhi)、工作溫度、法蘭執行標(biao)準及密封面形式等(deng)。