<dfn id='oRzdP'><optgroup id='EJvGp'></optgroup></dfn><tfoot id='eyhMN'><bdo id='Lnxrb'><div id='ECbCI'></div><i id='cC8sC'><dt id='Vn5p7'></dt></i></bdo></tfoot>

A494 CU5MCuC球閥是一種殼體(ti)(ti)由ASTM A494 Gr. CU5MCuC鑄造成型,球體(ti)(ti)和(he)(he)閥(fa)桿及(ji)閥(fa)座等(deng)采(cai)用(yong)Incoloy825或(huo)Alloy825等(deng)鍛件或(huo)棒材加工而(er)(er)成,具(ju)有(you)(you)截斷、開放和(he)(he)適度(du)節流的(de)(de)功能(neng)(neng),對(dui)硫酸及(ji)磷(lin)酸具(ju)有(you)(you)強耐應(ying)力腐(fu)(fu)蝕(shi)(shi)(shi)和(he)(he)耐縫(feng)蝕(shi)(shi)(shi)性(xing)(xing)(xing)能(neng)(neng)的(de)(de)英康洛(luo)依合金(jin)球閥(fa)。該閥(fa)主體(ti)(ti)部件所使(shi)用(yong)的(de)(de)材料(liao)為鎳、鉻(ge)和(he)(he)鐵的(de)(de)質量分數均(jun)較高(gao),并含少量金(jin)屬元素(su)鉬、銅和(he)(he)鈦(或(huo)鈮)的(de)(de)鎳基(ji)合金(jin),除有(you)(you)很高(gao)的(de)(de)機械(xie)性(xing)(xing)(xing)能(neng)(neng)外,還具(ju)有(you)(you)優(you)良的(de)(de)抗(kang)(kang)點(dian)蝕(shi)(shi)(shi)和(he)(he)縫(feng)隙腐(fu)(fu)蝕(shi)(shi)(shi)性(xing)(xing)(xing)能(neng)(neng),且不易產生氯離子(zi)應(ying)力腐(fu)(fu)蝕(shi)(shi)(shi)裂紋,有(you)(you)較好(hao)(hao)的(de)(de)耐氧(yang)化(hua)性(xing)(xing)(xing)和(he)(he)非氧(yang)化(hua)性(xing)(xing)(xing)熱酸能(neng)(neng)力,在溫(wen)度(du)高(gao)達(da)550℃的(de)(de)高(gao)溫(wen)時(shi)都具(ju)有(you)(you)很好(hao)(hao)的(de)(de)力學性(xing)(xing)(xing)能(neng)(neng)。本產品(pin)還能(neng)(neng)抗(kang)(kang)許多酸和(he)(he)氧(yang)化(hua)性(xing)(xing)(xing)及(ji)還原性(xing)(xing)(xing)介質的(de)(de)混合酸的(de)(de)侵蝕(shi)(shi)(shi),它有(you)(you)較高(gao)的(de)(de)鎳含量,加上鉬與銅,使(shi)得它對(dui)硫酸和(he)(he)磷(lin)酸有(you)(you)優(you)異的(de)(de)耐蝕(shi)(shi)(shi)性(xing)(xing)(xing),而(er)(er)且能(neng)(neng)抗(kang)(kang)幾(ji)乎所有(you)(you)濃度(du)和(he)(he)溫(wen)度(du)的(de)(de)硝酸溶(rong)液(ye)的(de)(de)浸(jin)蝕(shi)(shi)(shi),因此(ci),特適用(yong)于高(gao)溫(wen)、高(gao)壓(ya)和(he)(he)高(gao)腐(fu)(fu)蝕(shi)(shi)(shi)性(xing)(xing)(xing)介質管道。

| 序號 | 部件名稱 | 材料名稱 | |||

| 1 | 閥 體 | A494 CU5MCuC | UNS N08826 | Incoloy825 | Alloy825 |

| 2 | 閥 體 蓋 | A494 CU5MCuC | UNS N08826 | Incoloy825 | Alloy825 |

| 3 | 閥 座 | R-PTFE、PTFE、TEFLON、NYLON、PPL、PEEK、DEVLON、INCOLOY825+HF | |||

| 4 | 球 體 | Incoloy825 | Incoloy825 | Incoloy825 | Incoloy825 |

| 5 | 閥 桿 | Incoloy825 | Incoloy825 | Incoloy825 | Incoloy825 |

| 6 | 填 料 | GRAPHITE、R-PTFE、PTFE、TEFLON、PCTFE | |||

| 7 | 彈 簧 | Inconel750 | Inconel750 | Inconel750 | Inconel750 |

| 8 | 固 定 軸 | Incoloy825 | Incoloy825 | Incoloy825 | Incoloy825 |

| 公稱壓力Class | 150 | 300 | 600 | 900 |

| 殼體試驗壓力(MPa) | 3.0 | 7.5 | 16.5 | 22.5 |

| 高壓液體密封試驗壓力(MPa) | 2.2 | 5.5 | 12.1 | 16.5 |

| 低壓氣體密封試驗壓力(MPa) | 0.4~0.7 | 0.4~0.7 | 0.4~0.7 | 0.4~0.7 |

| 設計制造 | ASME B16.34-2013、API 608-2008、API 6D-2014 | |||

| 結構長度 | ASME B16.10-2017、API 6D-2014 | |||

| 法蘭標準 | ASME B16.5-2017、ASME B16.47-2017、ANSI B16.5-2013等 | |||

| 檢驗試驗 | API 598-2016、API 6D-2014 | |||

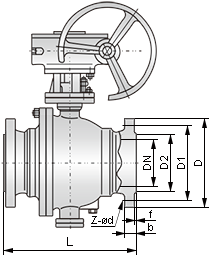

| 公稱壓力 Class | 公稱尺寸 NPS | 外形及連接尺寸/mm | |||||

| L | D | D1 | D2 | b-f | Z-?d | ||

| 150 | ? | 108 | 90 | 60.3 | 34.9 | 9.6-1.6 | 4-16 |

| ? | 117 | 100 | 69.9 | 42.9 | 11.2-1.6 | 4-16 | |

| 1 | 127 | 110 | 79.4 | 50.8 | 12.7-1.6 | 4-16 | |

| 1 ? | 140 | 115 | 88.9 | 63.5 | 14.3-1.6 | 4-16 | |

| 1 ? | 165 | 125 | 98.4 | 73.0 | 15.9-1.6 | 4-16 | |

| 2 | 178 | 150 | 120.7 | 92.1 | 17.5-1.6 | 4-19 | |

| 2 ? | 190 | 180 | 139.7 | 104.8 | 20.7-1.6 | 4-19 | |

| 3 | 203 | 190 | 152.4 | 127.0 | 22.3-1.6 | 4-19 | |

| 4 | 229 | 230 | 190.5 | 157.2 | 22.3-1.6 | 8-19 | |

| 5 | 356 | 255 | 215.9 | 185.7 | 22.3-1.6 | 8-22.5 | |

| 6 | 394 | 280 | 241.3 | 215.9 | 23.9-1.6 | 8-22.5 | |

| 8 | 457 | 345 | 298.5 | 269.9 | 27.0-1.6 | 8-22.5 | |

| 10 | 533 | 405 | 362.0 | 323.8 | 28.6-1.6 | 12-25.5 | |

| 12 | 610 | 485 | 431.8 | 381.0 | 30.2-1.6 | 12-25.5 | |

| 14 | 686 | 535 | 476.3 | 412.8 | 33.4-1.6 | 12-28.5 | |

| 16 | 762 | 595 | 539.8 | 469.9 | 35.0-1.6 | 16-28.5 | |

| 18 | 864 | 635 | 577.9 | 533.4 | 38.1-1.6 | 16-32 | |

| 20 | 914 | 700 | 635.0 | 584.2 | 41.3-1.6 | 20-32 | |

| 22 | 1016 | 750 | 692.2 | 641.4 | 44.5-1.6 | 20-35 | |

| 24 | 1067 | 815 | 749.3 | 692.2 | 46.1-1.6 | 20-35 | |

| 表中未列出的其他規格尺寸,請咨詢汗越閥門技術部! | |||||||