<tr id='ppmmu'><strong id='ppmmu'></strong><small id='ppmmu'></small><button id='ppmmu'></button><li id='ppmmu'><noscript id='ppmmu'><big id='ppmmu'></big><dt id='ppmmu'></dt></noscript></li></tr><ol id='ppmmu'><option id='ppmmu'><table id='ppmmu'><blockquote id='ppmmu'><tbody id='ppmmu'></tbody></blockquote></table></option></ol><u id='ppmmu'></u><kbd id='ppmmu'><kbd id='ppmmu'></kbd></kbd>

C95800球閥是(shi)一種(zhong)閥(fa)體由ASTM B148 UNS C95800鑄件(jian)加工而成(cheng),適用(yong)(yong)于公稱壓力(li)不(bu)大于PN40,工作溫度為(wei)(wei)-40℃~300℃的(de)(de)(de)海水(shui)、濃(nong)鹽(yan)(yan)水(shui)、硫酸鹽(yan)(yan)和各種(zhong)氯化(hua)(hua)(hua)物(wu)溶液等腐(fu)蝕(shi)性(xing)介質的(de)(de)(de)鎳鋁青(qing)銅(tong)(tong)球閥(fa)。該閥(fa)主(zhu)體部(bu)件(jian)所使用(yong)(yong)的(de)(de)(de)材質系高強度耐(nai)磨耐(nai)蝕(shi)青(qing)銅(tong)(tong)合金,化(hua)(hua)(hua)學成(cheng)分(質量(liang)(liang)分數)范圍為(wei)(wei)Cu≥79.0%,8.5%~9.5%的(de)(de)(de)Al,3.5%~4.5%的(de)(de)(de)Fe,0.8%~1.5%的(de)(de)(de)Mn,4.0%~5.0%的(de)(de)(de)Ni,Si≤0.10%,Pb≤0.03%,其(qi)(qi)中(zhong)含鐵量(liang)(liang)不(bu)超(chao)過含鎳量(liang)(liang),其(qi)(qi)金相(xiang)(xiang)顯微組織為(wei)(wei)α相(xiang)(xiang)+Al相(xiang)(xiang)+Fe-Al相(xiang)(xiang)+к相(xiang)(xiang),α相(xiang)(xiang)是(shi)鋁溶于銅(tong)(tong)中(zhong)的(de)(de)(de)固溶體,具有面心立方晶(jing)格,有較高的(de)(de)(de)力(li)學性(xing)能(neng)和塑性(xing)變(bian)形能(neng)力(li),是(shi)鋁青(qing)銅(tong)(tong)的(de)(de)(de)基(ji)本組成(cheng)相(xiang)(xiang),Ni-Al相(xiang)(xiang)與Fe-Al相(xiang)(xiang)為(wei)(wei)體心立方晶(jing)格,在(zai)(zai)(zai)合金中(zhong)起(qi)到細(xi)化(hua)(hua)(hua)晶(jing)粒和沉定硬化(hua)(hua)(hua)作用(yong)(yong),к相(xiang)(xiang)其(qi)(qi)實(shi)是(shi)Ni-Fe-Al的(de)(de)(de)化(hua)(hua)(hua)合物(wu),為(wei)(wei)有序體心立方晶(jing)格,硬度較高。本產品(pin)能(neng)在(zai)(zai)(zai)300℃以下工況使用(yong)(yong),綜合力(li)學性(xing)能(neng)較好,在(zai)(zai)(zai)海水(shui)及(ji)濃(nong)鹽(yan)(yan)水(shui)中(zhong)有高抗腐(fu)蝕(shi)、侵蝕(shi)性(xing)能(neng)。

| 序號 | 部件名稱 | 材料名稱 | |||

| 1 | 閥 體 | B148 C95800 | B148 UNS C95800 | B148 UNS No. C95800 | ZCuAl9Fe4Ni4Mn2 |

| 2 | 連 接 體 | B148 C95800 | B148 UNS C95800 | B148 UNS No. C95800 | ZCuAl9Fe4Ni4Mn2 |

| 3 | 閥 座 | R-PTFE、PTFE、TEFLON、NYLON、PPL、PEEK、DEVLON、B148 UNS C95800+HF | |||

| 4 | 球 體 | B148 C95800 | B148 UNS C95800 | B148 UNS No. C95800 | ZCuAl9Fe4Ni4Mn2 |

| 5 | 閥 桿 | B148 C95800 | B148 UNS C95800 | B148 UNS No. C95800 | ZCuAl9Fe4Ni4Mn2 |

| 6 | 填 料 | GRAPHITE、R-PTFE、PTFE、TEFLON、PCTFE | |||

| 7 | 螺 栓 | A193 B8M | A193 B8M | A193 B8M | A193 B8M |

| 8 | 螺 母 | A194 8M | A194 8M | A194 8M | A194 8M |

| 公稱壓力Class | 150 | 300 | 600 | 900 |

| 殼體試驗壓力(MPa) | 3.0 | 7.5 | 16.5 | 22.5 |

| 液體高壓密封試驗壓力(MPa) | 2.2 | 5.5 | 12.1 | 16.5 |

| 氣體低壓密封試驗壓力(MPa) | 0.4~0.7 | 0.4~0.7 | 0.4~0.7 | 0.4~0.7 |

| 設計制造 | GB/T 12237、GB/T 21385、ASME B16.34、API 608、API 6D | |||

| 結構長度 | GB/T 12221、ASME B16.10、API 6D | |||

| 法蘭標準 | JB/T 79、GB/T 9113、HG/T 20592、HG/T 20615、SH/T 3406、ASME B16.5等 | |||

| 檢驗試驗 | GB/T 26480、JB/T 9092、API 598、API 6D | |||

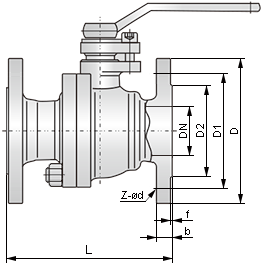

| 公稱壓力 Class | 公稱尺寸 NPS | 外形及連接尺寸/mm | |||||

| L | D | D1 | D2 | b-f | Z-?d | ||

| 150 | ? | 108 | 90 | 60.3 | 34.9 | 9.6-1.6 | 4-16 |

| ? | 117 | 100 | 69.9 | 42.9 | 11.2-1.6 | 4-16 | |

| 1 | 127 | 110 | 79.4 | 50.8 | 12.7-1.6 | 4-16 | |

| 1 ? | 140 | 115 | 88.9 | 63.5 | 14.3-1.6 | 4-16 | |

| 1 ? | 165 | 125 | 98.4 | 73.0 | 15.9-1.6 | 4-16 | |

| 2 | 178 | 150 | 120.7 | 92.1 | 17.5-1.6 | 4-19 | |

| 2 ? | 190 | 180 | 139.7 | 104.8 | 20.7-1.6 | 4-19 | |

| 3 | 203 | 190 | 152.4 | 127.0 | 22.3-1.6 | 4-19 | |

| 4 | 229 | 230 | 190.5 | 157.2 | 22.3-1.6 | 8-19 | |

| 5 | 356 | 255 | 215.9 | 185.7 | 22.3-1.6 | 8-22.5 | |

| 6 | 394 | 280 | 241.3 | 215.9 | 23.9-1.6 | 8-22.5 | |

| 8 | 457 | 345 | 298.5 | 269.9 | 27.0-1.6 | 8-22.5 | |

| 10 | 533 | 405 | 362.0 | 323.8 | 28.6-1.6 | 12-25.5 | |

| 12 | 610 | 485 | 431.8 | 381.0 | 30.2-1.6 | 12-25.5 | |

| 表中未列出的其他規格尺寸,請咨詢汗越閥門技術部! | |||||||

如果你需訂購我廠不銹鋼球閥系(xi)列產品,咨詢(xun)時請(qing)說明(ming)結(jie)構形式(shi),公(gong)稱通徑、公(gong)稱壓力、閥體(ti)和(he)內(nei)件材質、使用介質和(he)工作溫度、端部連接方(fang)式(shi)等(deng),本產品可根據工況需要設計(ji)成浮動球(qiu)(qiu)(qiu)球(qiu)(qiu)(qiu)閥、固(gu)定球(qiu)(qiu)(qiu)球(qiu)(qiu)(qiu)閥、三通球(qiu)(qiu)(qiu)閥(Y型(xing)(xing)、T型(xing)(xing)、L型(xing)(xing))、四通球(qiu)(qiu)(qiu)閥、V型(xing)(xing)球(qiu)(qiu)(qiu)閥及(ji)偏(pian)心(xin)半球(qiu)(qiu)(qiu)閥等(deng)。