<bdo id='ylyt0'></bdo><ul id='gLuty'></ul>

氣動噴煤球閥由(you)卸灰球(qiu)(qiu)閥(fa)和氣(qi)(qi)(qi)(qi)動(dong)(dong)執行機構兩部分組成,外裝控(kong)制系統,其開啟(qi)和關閉(bi)動(dong)(dong)作是由(you)氣(qi)(qi)(qi)(qi)缸(gang)驅使閥(fa)桿轉(zhuan)(zhuan)動(dong)(dong),從而帶動(dong)(dong)球(qiu)(qiu)體在(zai)閥(fa)腔(qiang)(qiang)(qiang)(qiang)內(nei)正反(fan)向(xiang)(xiang)回(hui)轉(zhuan)(zhuan)90°來實(shi)現(xian)的。如需(xu)開啟(qi)閥(fa)門(men)時(shi)(shi),使電(dian)磁換向(xiang)(xiang)閥(fa)得電(dian),此(ci)時(shi)(shi),氣(qi)(qi)(qi)(qi)源由(you)氣(qi)(qi)(qi)(qi)缸(gang)的A腔(qiang)(qiang)(qiang)(qiang)進入(ru),從B腔(qiang)(qiang)(qiang)(qiang)排出(chu),推動(dong)(dong)左(zuo)(zuo)右(you)活塞向(xiang)(xiang)相(xiang)反(fan)方向(xiang)(xiang)運動(dong)(dong),使輸出(chu)軸帶動(dong)(dong)球(qiu)(qiu)體逆時(shi)(shi)針旋轉(zhuan)(zhuan)90°,連通左(zuo)(zuo)右(you)閥(fa)體組成的通道(dao),閥(fa)處于直通狀(zhuang)態(tai),相(xiang)反(fan),要關閉(bi)閥(fa)門(men)時(shi)(shi),電(dian)磁換向(xiang)(xiang)閥(fa)失電(dian),從氣(qi)(qi)(qi)(qi)缸(gang)的B腔(qiang)(qiang)(qiang)(qiang)進氣(qi)(qi)(qi)(qi),由(you)A腔(qiang)(qiang)(qiang)(qiang)排氣(qi)(qi)(qi)(qi),推動(dong)(dong)兩活塞向(xiang)(xiang)中(zhong)間移動(dong)(dong),使轉(zhuan)(zhuan)動(dong)(dong)軸帶動(dong)(dong)圓(yuan)球(qiu)(qiu)順時(shi)(shi)針轉(zhuan)(zhuan)動(dong)(dong)90°,斷開左(zuo)(zuo)右(you)閥(fa)體組成的通道(dao),閥(fa)處于切(qie)斷狀(zhuang)態(tai)。本產品特(te)適用于煤粉(fen)噴吹的氣(qi)(qi)(qi)(qi)固二相(xiang)介質中(zhong),在(zai)閥(fa)門(men)開啟(qi)向(xiang)(xiang)高(gao)爐(lu)噴吹煤粉(fen)時(shi)(shi),不(bu)會積灰卡住,而閥(fa)門(men)關閉(bi)后,又(you)能很好的密封,不(bu)會產生(sheng)泄漏。

| 序號 | 部件名稱 | 材料名稱 | ||||

| 1 | 閥 體 | WCB | CF8 | CF3 | CF8M | CF3M |

| 2 | 左 閥 體 | WCB | CF8 | CF3 | CF8M | CF3M |

| 3 | 上下閥桿 | 2Cr13 | 304 | 304L | 316 | 316L |

| 4 | 球 體 | A105 | 304 | 304L | 316 | 316L |

| 5 | 閥 座 | 增強耐磨耐高溫四氟、對位聚苯、聚醚醚酮、A105+硬鉻、不銹鋼+硬質合金 | ||||

| 6 | 支 撐 圈 | 2Cr13 | 304 | 304L | 316 | 316L |

| 7 | 填料壓板 | WCB | CF8 | CF3 | CF8M | CF3M |

| 8 | 填 料 | GRAPHITE | GRAPHITE | GRAPHITE | GRAPHITE | GRAPHITE |

| 9 | 底 蓋 | Q235-B | 304 | 304L | 316 | 316L |

| 公稱壓力PN(MPa) | 0.25 | 0.6 | 1.0 | 1.6 | 2.5 |

| 殼體試驗壓力(MPa) | 0.375 | 0.9 | 1.5 | 2.4 | 3.75 |

| 高壓液體密封試驗壓力(MPa) | 0.275 | 0.66 | 1.1 | 1.76 | 2.75 |

| 低壓氣體密封試驗壓力(MPa) | 0.275 | 0.6 | 0.6 | 0.6 | 0.6 |

| 設計制造 | GB/T 12237-2021 石油、石化及相關工業用的鋼制球閥 | ||||

| 結構長度 | GB/T 12221-2005 金屬閥門 結構長度 | ||||

| 法蘭尺寸 | JB/T 79-2015、GB/T 9124.1-2019、HG/T 20592-2009等 | ||||

| 檢驗試驗 | GB/T 26480-2011 閥門的檢驗與試驗 | ||||

| 可配附件 | 信號反饋裝置、電磁閥、空氣過濾減壓閥、手動機構等 | ||||

| 氣源壓力 | 0.4MPa ~ 0.7MPa | ||||

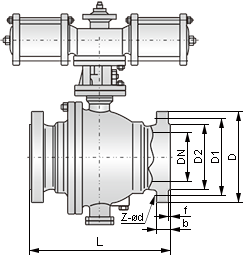

| 公稱壓力 PN | 公稱通徑 DN | 外形及連接尺寸/mm | |||||

| L | D | D1 | D2 | b-f | Z-?d | ||

| 2.5 ~ 6 | 150 | 400 | 265 | 225 | 202 | 18-3 | 8-18 |

| 200 | 500 | 320 | 280 | 258 | 20-3 | 8-18 | |

| 250 | 600 | 375 | 335 | 312 | 22-3 | 12-18 | |

| 300 | 700 | 440 | 395 | 365 | 22-4 | 12-22 | |

| 350 | 800 | 490 | 445 | 415 | 22-4 | 12-22 | |

| 400 | 900 | 540 | 495 | 465 | 22-4 | 16-22 | |

| 450 | 1000 | 595 | 550 | 520 | 22-4 | 16-22 | |

| 500 | 1000 | 645 | 600 | 570 | 24-4 | 20-22 | |

| 600 | 1067 | 755 | 705 | 670 | 30-5 | 20-26 | |

| 700 | 1200 | 860 | 810 | 775 | 30-5 | 24-26 | |

| 表中未列出的其他規格尺寸,請咨詢汗越閥門技術部! | |||||||